Another example from the company Ignetas UAB, which is a mid-size company, working in the subcontracting field that offers such services as robot welding parts, over moulding parts, semi-automatic and manual riveting parts and complex assembly parts. The company also has some CNC milling machines. They had the task of reducing the production time for one specific part which they are producing from an aluminium profile.

They are using a small 3 axis vertical machine (table size 300x250mm) for this task. The part is small and it also has some milling and drilling operations and 3 setups are needed. A very short cycle time leaves no space for the operator to do any additional work between cycle’s start and end.

Using traditional machine vices one-part production time including all setup’s was 2min and 25s.

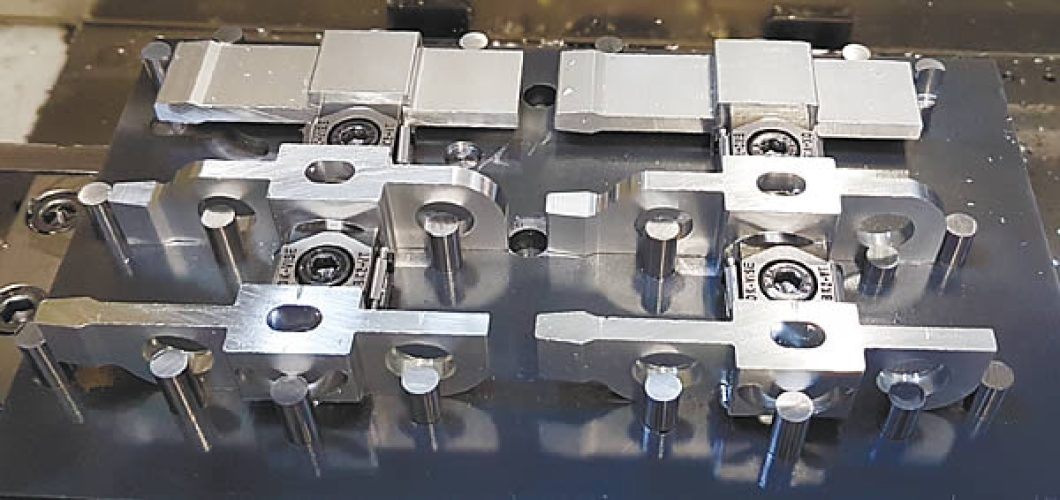

We recommended that they use low-profile clamps and make a dedicated pallet, where all setups are clamped at the same time, a total 6 pcs on one pallet. It enabled a production time of one part 1 min and 15s. Also the cycle time of one setup was 2.5 minutes. It allowed more time for the machine operator between cycles.