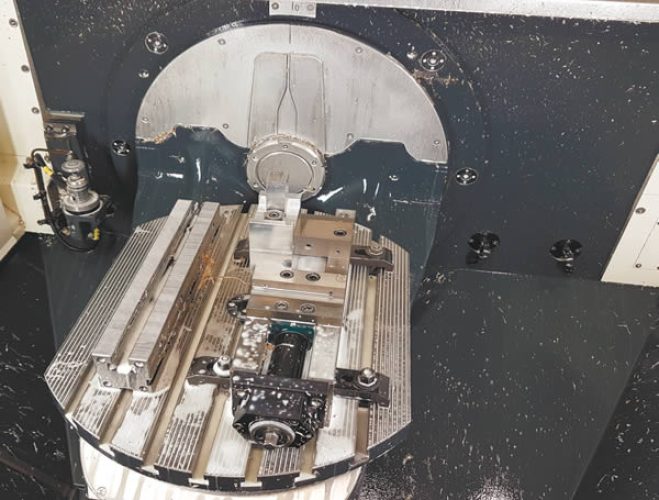

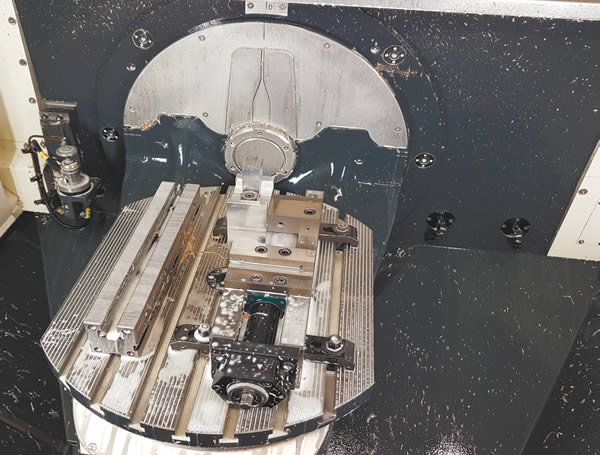

Our first case from Lithuania is a company using vertical 5 axis CNC machines. Machine table is Ø630x500mm. In the most case customer is using standard or dedicated 5-axis machine vises for 5 side machining. When part size is big enough, there is no problem with spindle/tool reachability of part from all 5 sides.

What to do if task is to cut complex part of size for example 25x25x25mm by using existing machine and table size. Specific vise is needed to lift part from table base to make possible to reach part with spindle/tool.

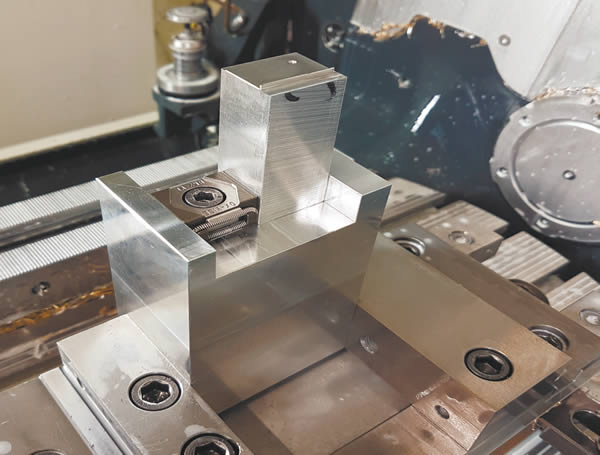

Customer started to use low-profile clamp. From the photos you can see simple solution: customer using standard machine vise for clamping block of aluminum, which we call riser. On top of riser one low-profile clamp is used to fix the blank material for 5 side machining. Solutions is simple and doesn’t requires big investments into specific clamping equipment.

Aluminum riser and OK-VISE low-profile clamp in combination for better accessibility at 5-axis table.