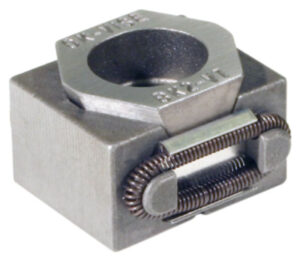

Product information - Low-profile clamp

OK-VISE clamps are a reliable basic component of any workholding and fixturing system.

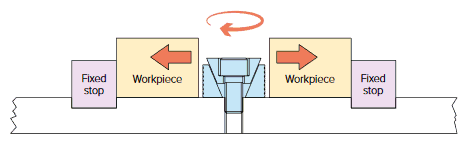

OK-VISE low-profile clamps expand when they are tightened down, simultaneously pressing the workpieces against the guide and preventing their movement. They are designed to take up very little space on the fastening base. Small in size, yet with an excellent clamping force of up to 150 kN, these clamps guarantee a holding capacity that clearly exceeds the load of machining forces. Fastening with only one bolt ensures quick set-up times.

Our low-profile clamps work just as well on single machines as in large Flexible Manufacturing Systems. In most straightforward applications, the only additional investment needed are the fixed stoppers.

Table of Contents

Jaw types

As a rule of thumb, a workpiece is held in a given direction by force closure or form closure. We offer several different jaw types for our clamps, depending on the needs of the workholding system. So, regardless of the workpiece form, material and parameters of machining process, always on optimal jaw type can be chosen from our supply.

Jaw combinations

It is also good to know that in clamps (as well as in most stopper modules) two different jaw types can be combined. In other words, You can order also low-profile clamps where jaws are not the same type – even if they might not be standard products.

If both jaws of the clamp are the same, typically there is one letter in the end of the code (like DK2-VT-T has two addtional piece jaws). If jaws are different, there are in most cases two letters in the end of the code (like BK2-VT-SR has one smooth jaw and one serrated). Same way clamps BK2-VT-BT and DK2-VT-BT posses one self-aligning jaw (“B”) and one jaw for addtional piece (“T”)

| jaw nr 2 / jaw nr 1 | R | S | D | Gn | +5 /+3 | C | H | V | T | E (or B) | |

Serrated basic version | R | SR | DR | RGn | +5R | CR | HR | VR | TR | B | |

| Smooth basic version | S | S | DS | SGn | +5S | CS | HS | VS | TS | ES | |

| Diamond coated surface | D | D | DGn | +5D | CD | HD | VD | TD | ED | ||

| Grip jaw models | Gn (*3) | Gn | +5Gn | CGn | HGn | VGn | TGn | EGn | |||

| Machinable jaw | +5 / +3 (*1) | +5 | |||||||||

| Cross V slot | C | +5C | C | HC | VC | TC | EC | ||||

| Horizontal V-slot | H | +5H | H | VH | TH | EH | |||||

| Vertical V-slot | V | +5V | V | TV | EV | ||||||

| Additional piece models | T | +5T | T | ET | |||||||

| Self adjustable jaw | E (or B) (*2) | +5E | E |

Clamp sizes and forces

OK-VISE low-profile clamps come in four different sizes (A, B, D, F) for metric bolts (M5, M8, M12, M16), while the D-Series Inch Model is made for a half-inch bolt.

| Size | A | B | D | D / inch | F |

| Bolt size (metric) | M5 | M8 | M12 | M16 | |

| Imperial bolt size | 3/16″ | 5/16″ | 1/2″ | 5/8″ | |

| Force up to (kN) | 10 | 25 | 90 | 90 | 150 |

| Force up to (lbs) | 2 200 | 5 600 | 20 000 | 20 000 | 33 000 |

| AMin…AMax (m Metric bolt size, compared to optimum | -2.9…+2.5 | -1.9…+3.0 | -3.3…+5.2 | -4.9…+3.3 | |

| Bolt offset (mm) | 2 x 0.7 | 2 x 1.2 | 2 x 1.1 | 2 x 1.7 |

In B-series clamp the maximum clamping force is 25 kN which corresponds the force in a typical machine vise! It is the most popular size today, followed by D-size which may be easier to handle manually and also the more popular in automated solutions.

The precision-ground surfaces of OK-VISE Low-profile clamps quarantee consistently accurate clamping force.

The manual clamping is normally applied using an allen key with torque guage, however a power tool can also be utilised for convenience. When actuated with a bolt the models with ground surfaces have a high accuracy response between torque and the clamp force The precision-ground surfaces of OK-VISE Low-profile clamps quarantee consistently accurate clamping force.

We have attached the torque-force graph to enable the most suitable clamping force & torque selection.

x = torque ( Nm), y = force ( kN )

Other clamp properties

In addition to above mentioned clamp sizes and various jaw types, OK-VISE clamp superior designs differ from its competition in a number of important ways

Pull-down clamps

Where standard model single-wedge clamps always keep workpieces steadily in place, not allowing

upward or downward movement, pull-down clamps also generate pull-down action and press workpieces towards the fixture base.

Stainless steel model

Originally designed for EDM applications, stainless steel clamp is used today in many harsh environments like welding appliations

Economy model (-O)

Some of our customers prefer our economy-series, which works sufficiently well in applications where absolute repeatability, high clamp accuracy and extremely high pressing forces are not necessary.

In economy model, only the bottom of the jaw is ground.

Our smallest series is only available as the economy model (AK2-VT-SO).

D-series inch models (-VTI, -WTI)

You can fasten the clamps with bolts of both metric and imperial dimensions for A-, B- and F-size clamps.

For D-size clamps, there are separate models to be used with an imperial half-inch bolt.

The center holes of inch-series wedges are wider in order to fit the half-inch socket head screw.

Accessories and spare parts

In addition to stoppers, side stoppers, side guides and parallels that are available in our modular and blank systems there are some components that are more specific for low-profile clamps.

These are for example additional pieces for jaws and various types of protection plates.