Tips for product selection

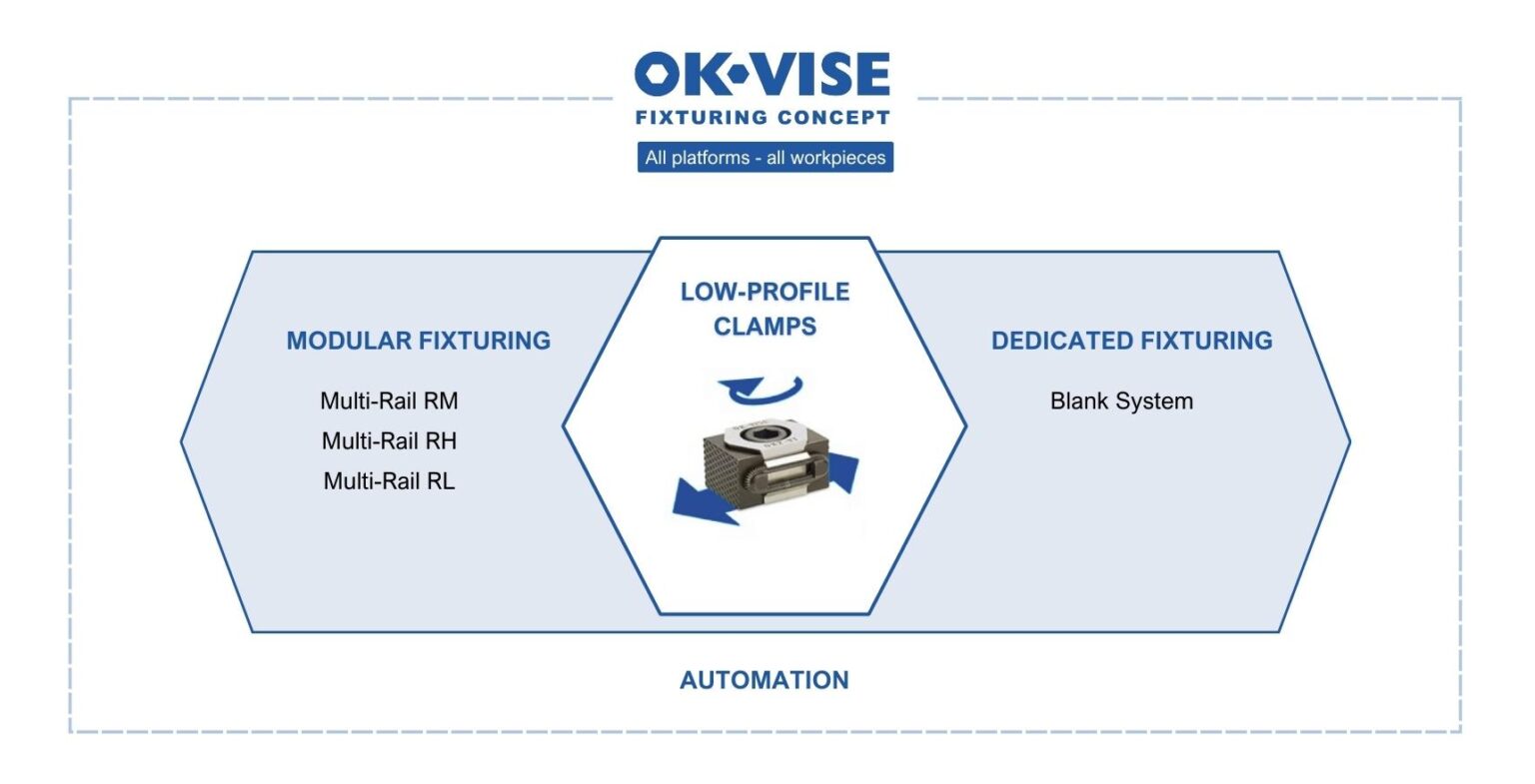

Modular fixturing vs. dedicated fixturing

In most cases machining a workpiece requires more than one fixture.

The fixture for a specific workpiece and a specific machining operation can be built by using modules for modular fixturing or dedicated fixturing.

A dedicated fixture is workpiece-specific, whereas a system built of generic-purpose components can be set up for a variety of workpieces.

Fixture built from modular fixturing components

- Modular system

- Off-the shelve availability of modules

- Possible modifications can be limited to individual modules

- Setup change can be normally done simply by moving the stop modules

Dedicated fixture

- Fixture can be easily optimized by any relevant criteria

- Even most extreme workpieces can be clamped

- Setup change must be done by changing the fixture

In addition to these extremes, many fixturing challenges can be solved using an innovative mix of dedicated and modular components