In the ever-evolving landscape of manufacturing, precision and adaptability are key factors in achieving optimal efficiency. When deciding how to secure the workpiece during machining processes, the choice between traditional fixtures and modular fixtures becomes crucial.

How do modular and traditional fixtures differ from each other?

Let’s start with the term ‘fixture.’ When compared to traditional machine vises, a fixture is, by definition, more product-specific. This means it can be optimized for a specific workpiece’s form, material, or machining operation.

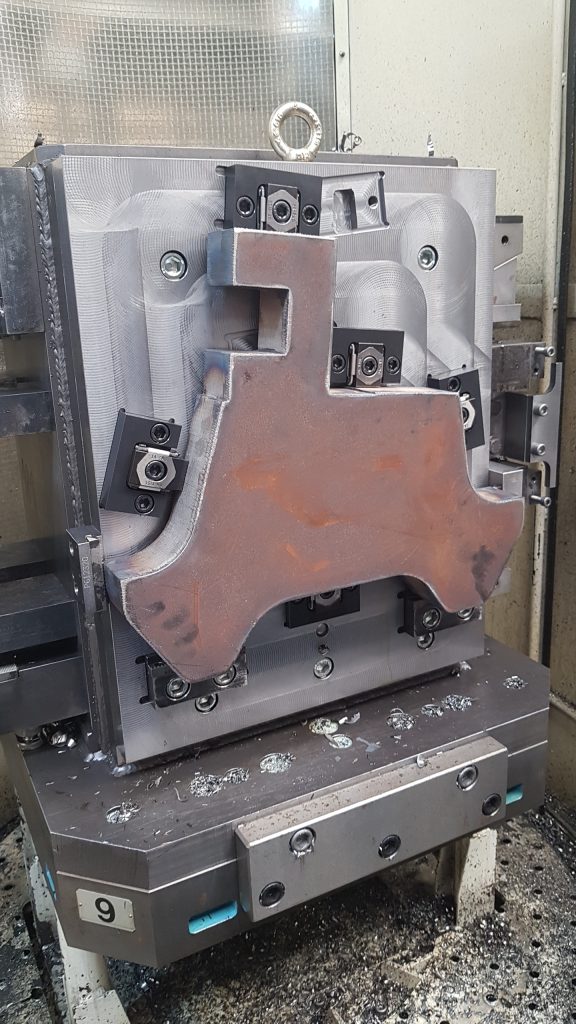

Old-school machining fixtures used to be steel or aluminum plates or tooling blocks, where pockets and holes were machined for the workpiece, and workholding clamps were installed to hold it. This approach is still valid in many companies, and the cost of the fixture is marginal when production volumes are high.

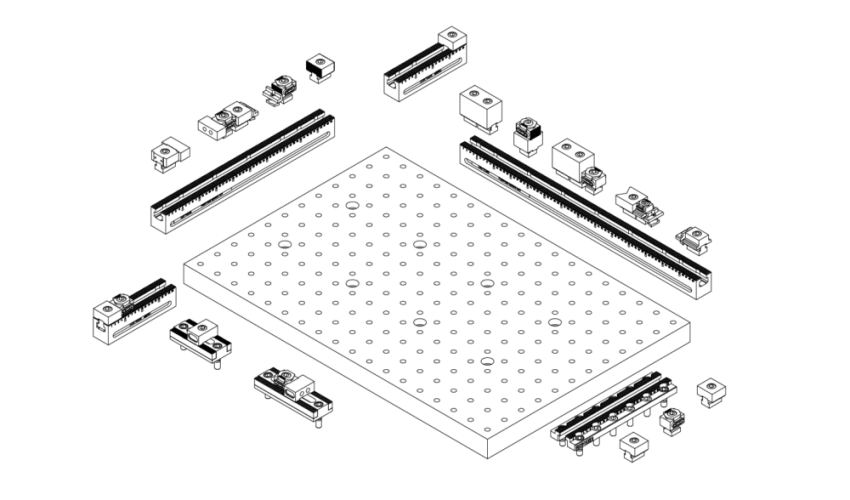

On the other hand, a modular fixturing system is a flexible and reconfigurable workholding system used in manufacturing and machining processes. Unlike traditional fixtures designed for specific workpieces, a modular fixture uses standardized components that can be easily assembled, disassembled, and rearranged to accommodate various workpiece shapes, sizes, and machining operations.

When should you use a modular fixture?

There are two main drivers to use modular machining fixtures instead of product-specific fixtures.

1. Delivery time: The delivery time can be faster if the modules for the fixture components are in stock. Typically, this is the case with modular workholding components. In the best-case scenario, you may already have a modular fixture available in your production that can be converted for another product in just a few minutes.

2. Cost: Most likely, a larger product family can be machined using the same base fixture, with only minor adjustments in stopper places and riser blocks. In most cases, one modular fixturing system is a more economical option than two dedicated ones. Since tooling departments no longer exist in all companies, fixture design and manufacturing are increasingly being outsourced. In these situations, the use of product-specific fixtures tends to be much more expensive than a modular approach.

Modular fixturing system manufacturers like OK-VISE produces fixture modules so that all kinds of workholding needs could be covered using a modular approach. However, all modular systems have their limitations but when used in the right situations, it can significantly boost productivity and lower costs.

Find out more what we can provide you in modular fixturing systems: OK-VISE Multi-Rail System

Learn more about Fixturing Concept idea: Fixturing Concept principle